Know What Your Total Labor Cost Is

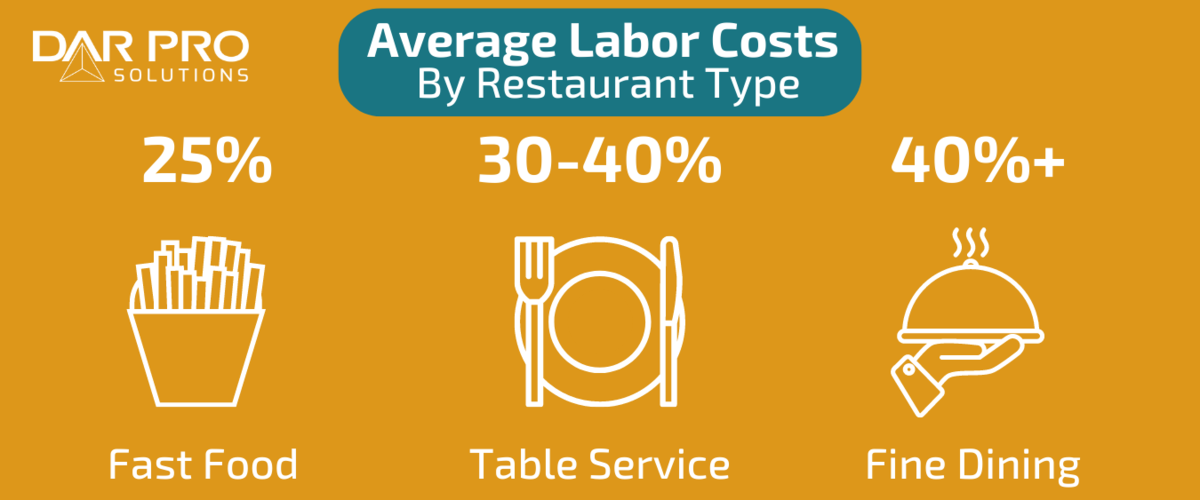

In order to reduce labor costs, you need to have an idea of what your total cost is and find out how efficiently or inefficiently you are spending on labor. Most restaurants’ labor costs comprise anywhere between 25-40 percent of its overall costs.

Whether it’s weekly, monthly or annually, calculate your total labor cost. It will not only give you a starting point as to how to trim the number, but it will also likely give you a hint as to where to start doing the trimming.

How do you calculate labor cost?

One efficient way to calculate labor costs is to do it by percentage of operating costs. You can do this in four easy steps:

- Determine the total amount your restaurant pays all employees throughout the specified time period you selected.

- Determine the restaurant’s total operating costs, not just sales, but all marketing, rent, food, drink, and other costs.

- Divide the total employee cost by your total operating costs.

- Multiply that by 100 and you will have your answer.

Labor costs are a controllable expense. Once you have a grasp on what your total labor costs are, you can now identify and implement impactful ways to cut labor costs and improve your bottom line.

Invest in Automation In Your Restaurant

Investing in automation is a crucial step in both reducing labor costs and combatting the widespread staffing shortages that are hurting the restaurant industry. Automation keeps your restaurant modern and makes your entire operation more efficient.

1. Customer-facing automation:

Reduce the amount of time your staff must spend unnecessarily pouring drinks, stocking cups and setting out utensils and condiments. Self-pour drink machines, condiment and utensil dispensers. Leave that part of the service experience up to the customer. It’ll make your lines shorter and your restaurant flow more efficiently, too.

2. Self-ordering and checkout kiosks

Take it a step further. If the style of your restaurant is conducive to it, look into using self-ordering kiosks and make the entire checkout process completely automated. Some restaurant concepts are even using AI Watson facial recognition software for ordering and transaction processes. Why have four employees manning cash registers at every lunch and dinner rush if you don’t have to? Let automation and the customer take care of that. It’ll reduce the number of employees you need per shift.

3. Automated equipment in the food-making process

Automation in the food-making process will reduce the manpower needed in the back of house. From automated pizza makers to burger flipping robots, the technology available to restaurants to make their food without manual labor is growing. And while it isn’t reasonable to have a completely automated kitchen to the point of no staffing needed, it’s worth looking into to reduce the number of staffers needed to man your kitchen on a daily basis.

4. Automated used cooking oil storage and transfer equipment

Used cooking oil recycling and equipment is likely not a top-of-mind concern for your business, but it can become an expensive hassle. Why have your staff waste shift time lugging a pot of hot cooking oil outside the kitchen to an outdoor bin? This is both dangerous and inefficient. It not only wastes time, but it could also lead to injury and workers’ compensation claims. Automate the process down to one touch of a button by implementing an automated tank. Direct connection cuts down the time spent handling oil from 30-45 minutes to just a couple of minutes. It’s also one less thing your staff has to worry about and one less job to assign someone to.

Cross Train Your Restaurant Staff

There's value in versatility. Cross training your staff to be able to handle a multitude of different roles throughout your restaurant is a useful practice, particularly during a time in which the industry is enduring staffing shortages.

Why have all four registers covered on a slow night? Or the same number of servers whether the dine-in area is packed to the gills or sparsely populated. It’s inefficient in many ways. But if those employees are trained to adequately serve in a variety of roles, you can have them help in other areas like busting tables, cleaning dishes or helping with the food preparation process. This will eventually make your scheduling more efficient as you will feel more comfortable assigning fewer employees per shift.

Versatility leads to better efficiency. It also works to the benefit of your employees in the long run as it broadens their skillset within the restaurant industry. It can also lead to longer employee retention and can cultivate a team-first environment that hinges upon doing whatever is needed at any given moment.

Optimize Your Employee Schedule

Made even easier by cross training your staff, it’s important to ensure that your scheduling practices are efficient. Make sure you are scheduling right amount of people and the right number of shift hours. If you routinely notice that you have employees looking for things to do or two people doing the job of one, it may mean that you are not optimizing your scheduling.

Knowing your slowest and busiest days helps in this process, too. Schedule in accordance with days you know are going to be busiest. Be sure to incorporate holidays into your thinking while doing this. Is Christmas or Easter particularly busy for your business? If so, then you should have more people on hand than you would on your average Tuesday dinner rush.

Utilizing a point-of-sale system will help with this as it will provide you with concrete data with which you can make scheduling decisions. Analyze patterns in traffic over time and staff accordingly based off it will save your business money via payroll and cut down on unnecessary staffing.

Cutting costs where it’s reasonably possible is a great way to keep your business’ operating costs under control. Reducing labor costs by using these tips should help the process.

DAR PRO Solutions provides used cooking oil recycling and grease trap maintenance service to commercial kitchens across the country. Our automated equipment program makes your grease recycling quicker, safer and more efficient. Reach out to a DAR PRO representative today and find out how your business can benefit from our program. Call us 24/7/365 at 855-DAR-PRO1 (855-327-7761).

Contact Sales

For customer service inquiries call our toll free number (855) 327-7761

By submitting this form I agree to the privacy policy including the usage of contact details to contact me for marketing purposes.