Unfiltered oil ruins even the best quality ingredients cooked in an expensive commercial fryer. Regular deep fryer oil filtering is a cornerstone to a successful operation.

Food Quality – Why Deep Fryer Oil Filtration is So Critical

Restaurant fryer oil quickly becomes contaminated with floating and suspended particles and sediment. Small bits of food are left in the cooking oil. Using dirty oil can discolor ingredients and frequently leads to bad-tasting food.

Inconsistent food quality leads to dissatisfied customers, and unfiltered oil leads directly to widely varying results. When the food’s color, smell, and taste are off, even a little, customers notice.

And in this age of instant broadcasting for online reviews, consistent, high-quality food is more important than ever. Fulfilling the expectations of every customer – every time – keeps those positive reviews coming, bringing in more guests!

If your kitchen staff consistently uses a cooking oil filter and serves great food, customers will keep coming back for more.

Increase Oil ROI for Higher Profits

Restaurant fryer oil costs, always one of the biggest in food prep, have grown even further. Cooking oil has always been an important expense to keep your eye on. Still, in the past two years, vegetable oil prices have soared well beyond other food inflation. Due to competition with biofuels, and drought, food oil prices have gone up over 70%.

To save costs, regular use of an oil filter machine makes sense when compared to replacing deep fryer oil every time. As cooking oil prices skyrocket, it’s time to take steps to make your oil last longer.

Challenges of Cooking Oil Filtration

Filtering out the food particles extends the life of your oil by protecting the color, smell, and taste of the food you prepare. It’s critical your kitchen staff ensures the cooking oil is consistently filtered on an optimized schedule to protect food quality.

Fortunately, current technology allows you to set a standardized filtration schedule ideal for your kitchen. Filtration technology monitors your filtration schedule, so you can have contaminants removed following a standard procedure.

Plus, train your kitchen staff to use their senses to carefully examine the oil (see), smell it, and taste the food! Have workers routinely skim off any food particles from the oil during the day, between filterings. Well-trained staff members can often tell the state of their restaurant fryer oil by just walking past the deep fryer!

Fryer manufacturers and other experts recommend cooking oil filtration twice daily after busy meal times. Set the clock.

Oil Filtration Systems – How to Filter Your Cooking Oil

Now that you know how important oil filtration is, you are faced with a choice. Will you choose a portable fryer filter machine or a built-in drawer filtration system?

Portable Fryer Filters

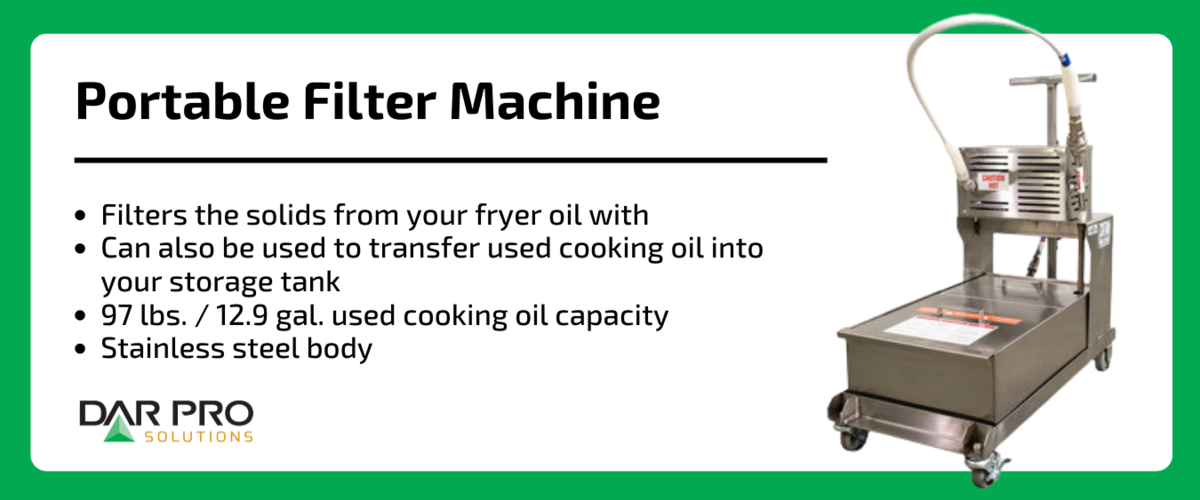

A portable filtration machine is an efficient step up from a completely manual filtering process. It costs less upfront than than a built-in, portable fryer filters are moved around the kitchen. You can use your portable filtration on several types of fryers, and the cart can transfer your used oil to the storage tank when it can’t be filtered anymore. Choose a portable filter unit based on the storage space you have available for when it’s not being used.

Built-In Fryer Filters

Some fryers come with a built-in filtration system, which is a big plus, as they filter the oil right within the unit. Although more expensive initially when purchasing your new fryers, built-in oil filtration is faster and safer. And you won’t need to use any kitchen storage space to house the unit as it is a series of drawers within the fryer itself. Also, with built-in filtration, your fryers may have a waste oil disposal port that allows you to install a connection directly to a used cooking oil tank and automatically discard oil.

The Bottom Line

Effective, efficient, safe oil filtration ensures longer oil life to maximize your oil ROI. Plus, it helps provide consistent, high-quality fried foods for customers.

DAR PRO Solutions provides safe and efficient used cooking oil recycling solutions to over 130,000 commercial kitchens across the country. Our program reduces hazards within commercial kitchens. Reach out to a DAR PRO representative today and find out how your business can benefit from our program. Call us 24/7/365 at 855-DAR-PRO1 (855-327-7761).

Contact Sales

For customer service inquiries call our toll free number (855) 327-7761

By submitting this form I agree to the privacy policy including the usage of contact details to contact me for marketing purposes.